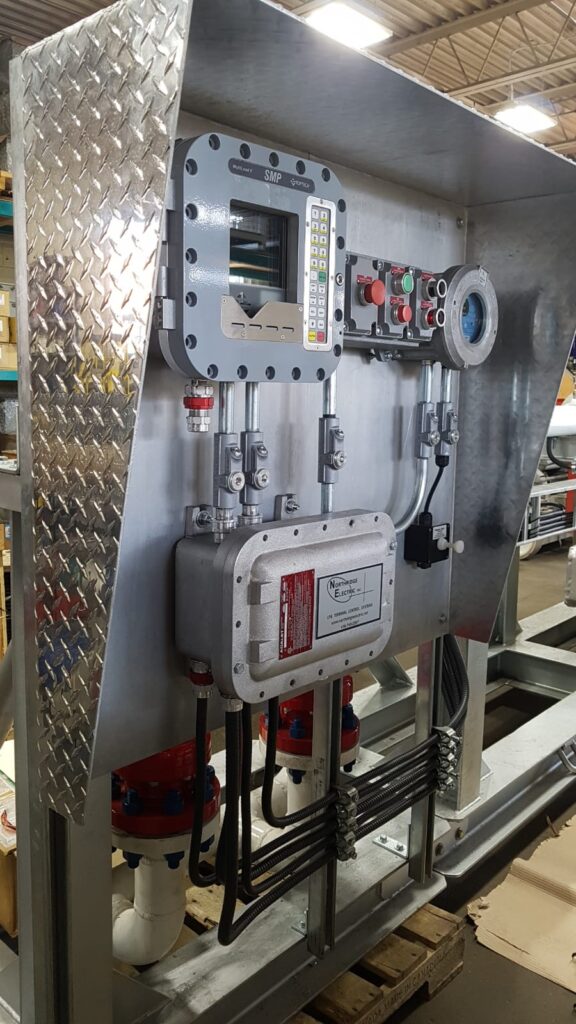

Northridge provides pre-assembled, fully integrated NGL and propane control assemblies that simplify terminal automation, improve safety, and ensure full compliance with industry regulations. Our systems are designed for hazardous environments, offering seamless integration with pumps, compressors, metering skids, and emergency shutdown systems.

With over 25 years of experience in oil and gas terminal automation, we provide:

Old-school systems rely on independent manual valves, pumps, emergency stops, and warning devices. This creates major safety and efficiency risks:

With Northridge’s pre-engineered explosion-proof PLC control assemblies, these risks are eliminated.

Northridge’s certified explosion-proof PLC control systems allow NGL and propane facilities to operate as one unified system—ensuring seamless automation, remote monitoring, and regulatory compliance.

Controls are assembled, tested, and certified before deployment, reducing errors and installation time.

Unlike the 25–50-week procurement industry norm, Northridge ships in 30 days or less with deep inventory support.

Local installers “connect the dots” without needing advanced technical expertise.

Built to UL and CSA standards, reducing inspection time and improving safety.

Systems communicate with each other, eliminating manual intervention and operator mistakes.

Our control assemblies are pre-assembled, pre-certified, and field-ready, designed to integrate seamlessly into NGL and propane terminals, propane facilities, and hazardous gas environments.

Our turnkey control assemblies eliminate the hassle of custom engineering work, on-site assembly, and last-minute compliance modifications—providing a seamless, ready-to-install solution for terminal automation.

Northridge’s pre-engineered explosion-proof control systems provide unparalleled safety, automation, and compliance for hazardous locations.

Northridge is a trusted provider of PLC controls for NGL and propane facilities, propane terminals, and hazardous industrial environments. With turnkey system integration, we handle design, fabrication, and testing before shipment, ensuring seamless on-site installation.

Unlike competitors, we maintain a deep inventory of stocked components, allowing for faster lead times and rapid deployment—cutting procurement times from 25–50 weeks to 30 days or less. Our end-to-end support covers everything from engineering and compliance to installation and long-term system service, so customers can rely on expert assistance throughout their operations. Built for long-term reliability, our systems are engineered to withstand extreme conditions and continuous operation, minimizing downtime and maximizing safety.

Don’t take risks with manual, outdated, or non-compliant control systems. Northridge provides certified, explosion-proof solutions for ultimate safety and operational efficiency.