Northridge provides full-service electrical design, fabrication, and automation for propane terminals, ensuring seamless system integration, compliance, and reliability. Our prefabricated solutions eliminate the need for piecemeal electrical systems—we handle everything from control-panel fabrication to PLC programming and field-ready installations.

With over 25 years of experience in hazardous location electrical design, we provide:

Many propane terminals struggle with outdated, manually operated, non-interlocked electrical systems, leading to operational inefficiencies, compliance risks, and high maintenance costs. Without a centralized, PLC-driven electrical design, facilities often experience:

Uncoordinated system operation – Pumps, compressors, and safety systems don’t communicate, leading to accidents and equipment damage.

Complicated installations – Manually assembling electrical components slows projects and increases installation errors.

Failed inspections and regulatory fines – Custom electrical setups often require additional engineering work to pass compliance standards.

A well-designed PLC-controlled electrical system simplifies operations, improves safety, and ensures your terminal meets industry regulations from day one while costing the same as a do-it-yourself system.

Building a safe, efficient, and compliant electrical system for a propane terminal requires deep industry expertise.

Northridge streamlines the process with expert-led electrical design and built-in compliance support, ensuring your terminal meets NFPA, OSHA, and NEC standards without delays.

Our pre-engineered solutions and PLC controls reduce safety risks by integrating automated controls, emergency shutoffs, and gas detection. This allows you to minimize human error and operational hazards. With efficient planning and seamless mechanical and electrical integration, we help lower project costs while delivering a future-proofed terminal that supports growth and scalability.

Comprehensive design that integrates electrical, mechanical, and safety systems for a seamless solution.

Built to meet NFPA, OSHA, and local compliance requirements, ensuring faster approvals and fewer roadblocks.

Reduces manual operations and human error, improving safety and operational efficiency using PLC controls for propane terminals.

Scalable solutions designed for midstream marketers, wholesalers, and bulk storage operators.

Streamlined planning and pre-engineered, stocked components minimize downtime, delays, and unexpected costs.

Designed for quick deployment with ongoing expert assistance to ensure smooth integration.

We handle every aspect of terminal electrical design and integration, providing a fully engineered, pre-certified solution that simplifies installation and long-term operation.

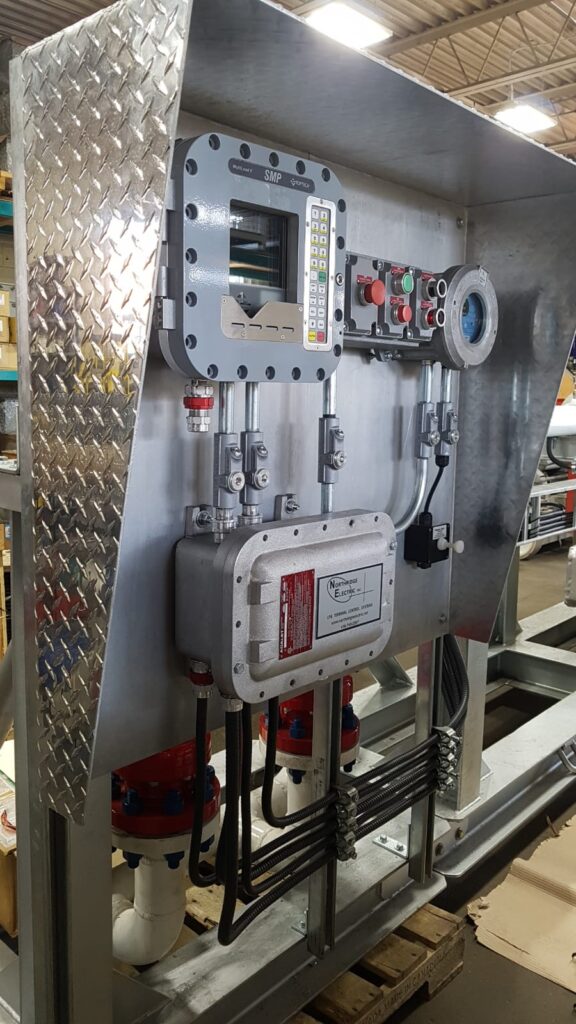

Northridge’s propane terminal design incorporates cutting-edge safety and automation features to ensure smooth operations, regulatory compliance, and reduced risk. Our systems are built for hazardous environments, providing reliable control and protection where it matters most.

We review all your equipment and discuss your requirements.

We discuss and recommend best practices as well as safety and productivity features that suit your needs.

We create a custom automation and electrical plan emphasizing safety.

We develop detailed schematics for seamless integration.

We build a central control panel, custom explosion-proof controls, and instrumentation. We assemble all hardware into easy-to-install assemblies.

Once shipped to the site, your electricians can easily connect the assemblies together using our provided drawings.

Our team comes to you for training, offering in-depth support and knowledge for your team.

Our detailed drawings of your terminal, online visibility and inventory of parts, allow us to provide expert support and rapid response to maximize your uptime.

Choosing the right partner for propane terminal design is critical to ensuring safety, compliance, and efficiency. Northridge brings industry-specific expertise and proven solutions that eliminate common pitfalls and delays. We have built our careers helping build safer, smarter terminals with confidence. Since 1997, we have been honored by the trust of industry leaders. We offer: